With some of the world’s largest digital printing presses, things at the Procedes Group are “a little different in size” compared to what you’re used to at home.

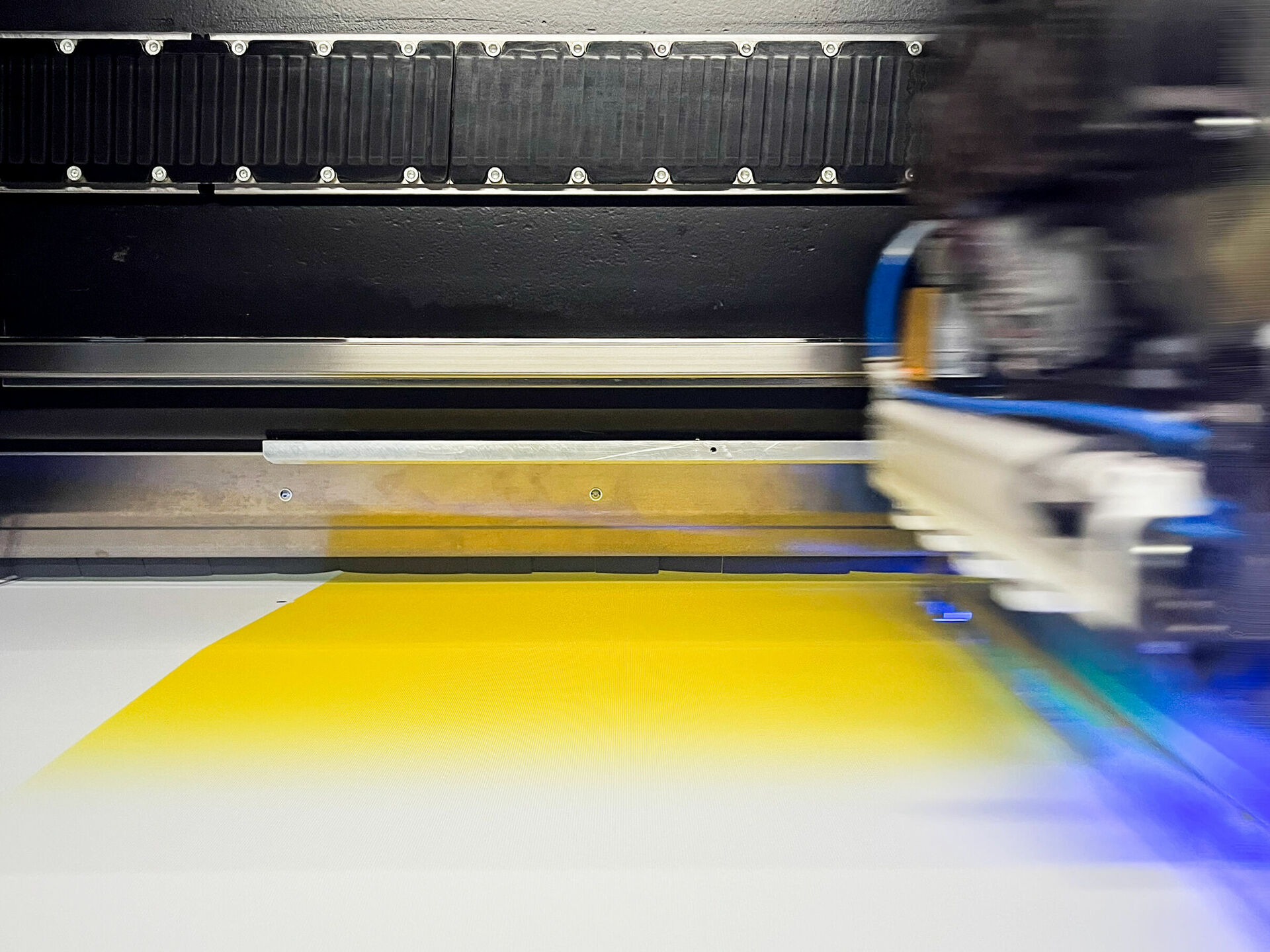

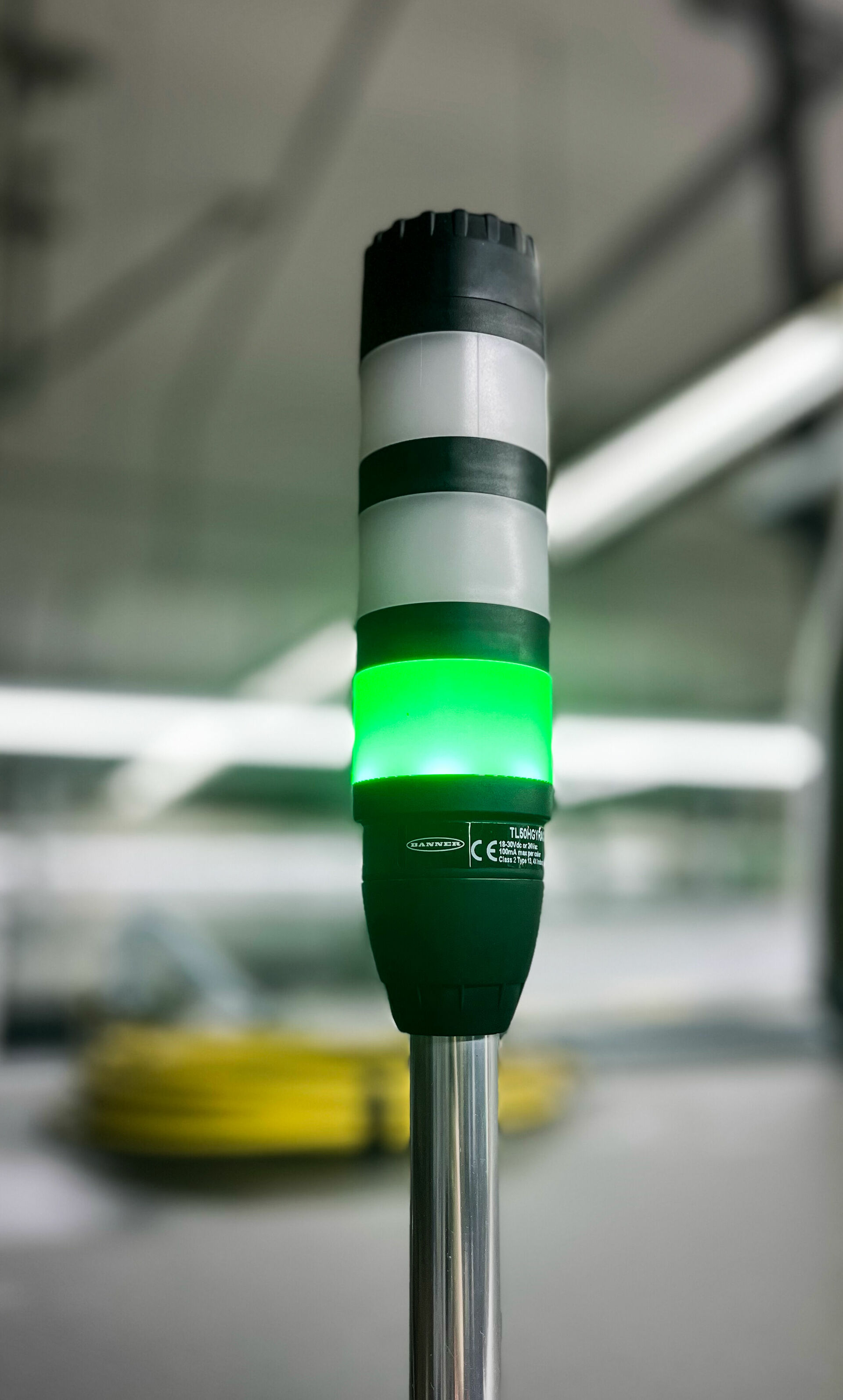

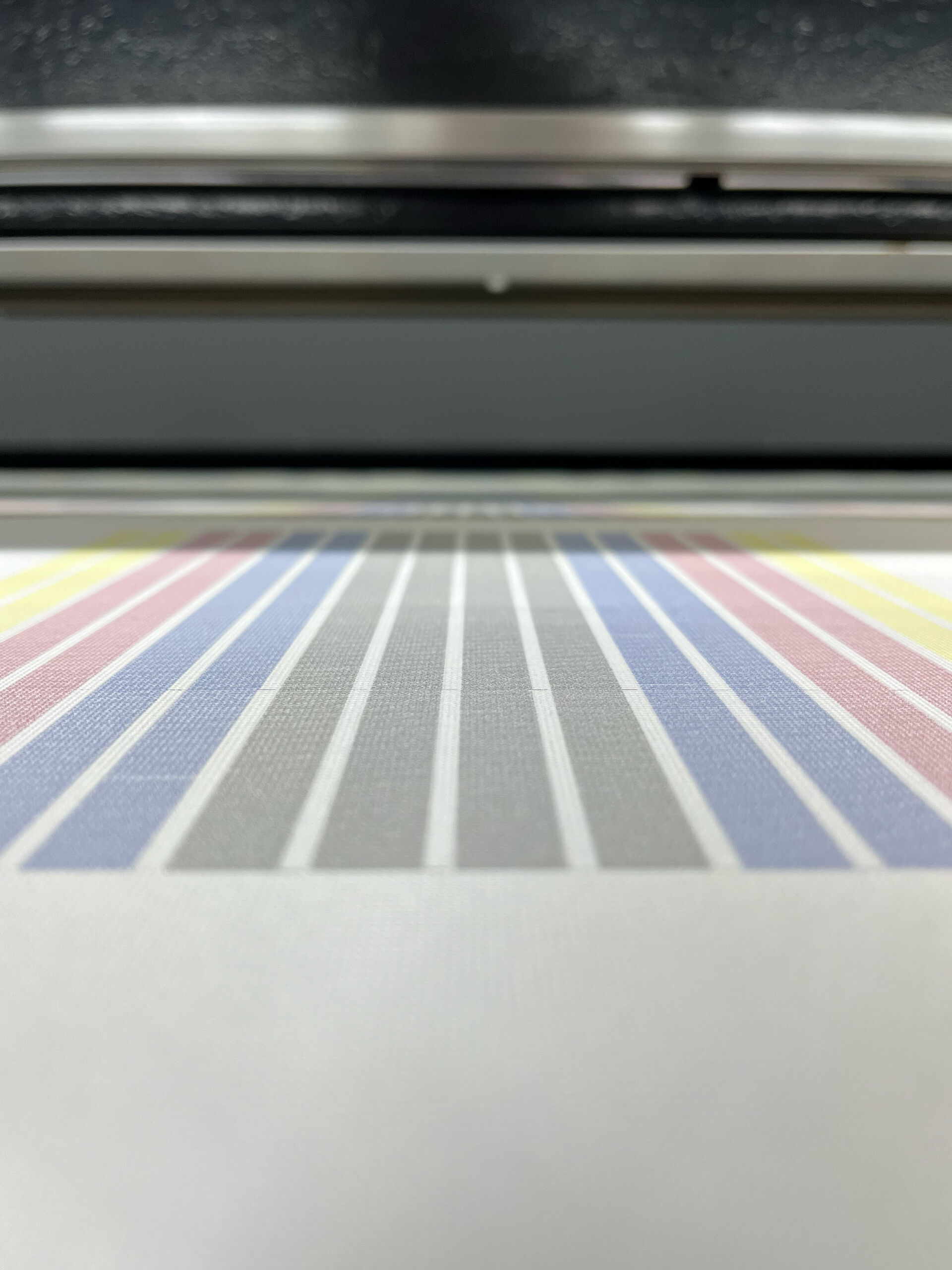

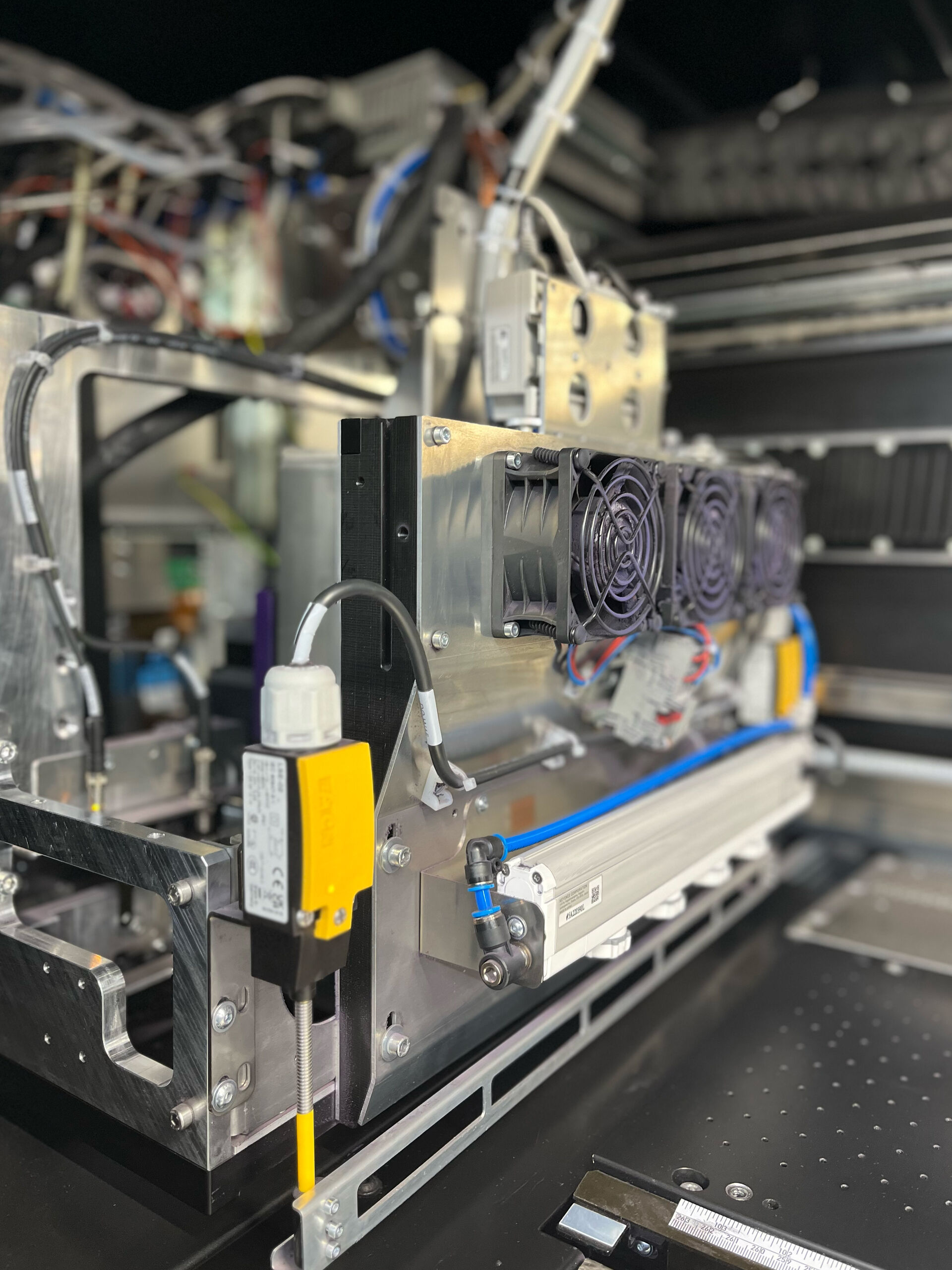

How different? Very! Our printers are over 26 feet long and can handle print widths of 16 feet. They operate at impressive speeds, producing up to 3,800 square feet of textile per hour. To put that into perspective, your entire living space could be covered in prints in no time.

Although we could cover floors, our primary focus is on delivering solutions for walls and ceilings. At the Procedes Group, we use both UV printing and dye-sublimation to ensure each project achieves its full potential. Here’s a breakdown of the advantages, disadvantages, and applications of both printing processes, so you can determine which one is best suited for your project.

- Vibrant, high quality, permanently dyed motifs

- Odorless prints

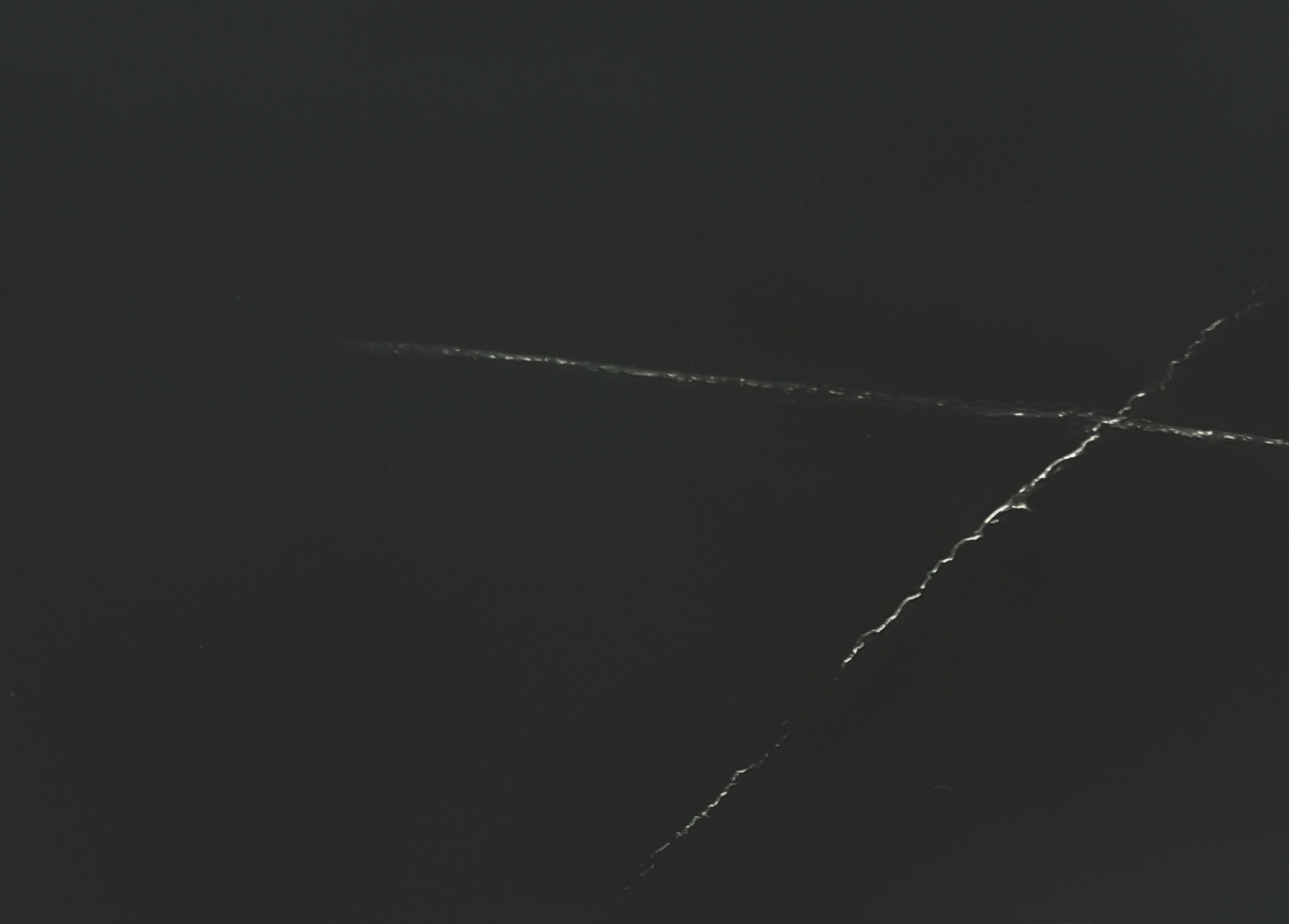

- Can’t be superficially damaged, there is no material to chip, peel or scratch

- Easier and cost-effective transport due to foldable prints (no need for oversized rolls)

- Material width up to 16 feet

- 4-color system (CMYK) + 2 special colors (light cyan, light magenta)

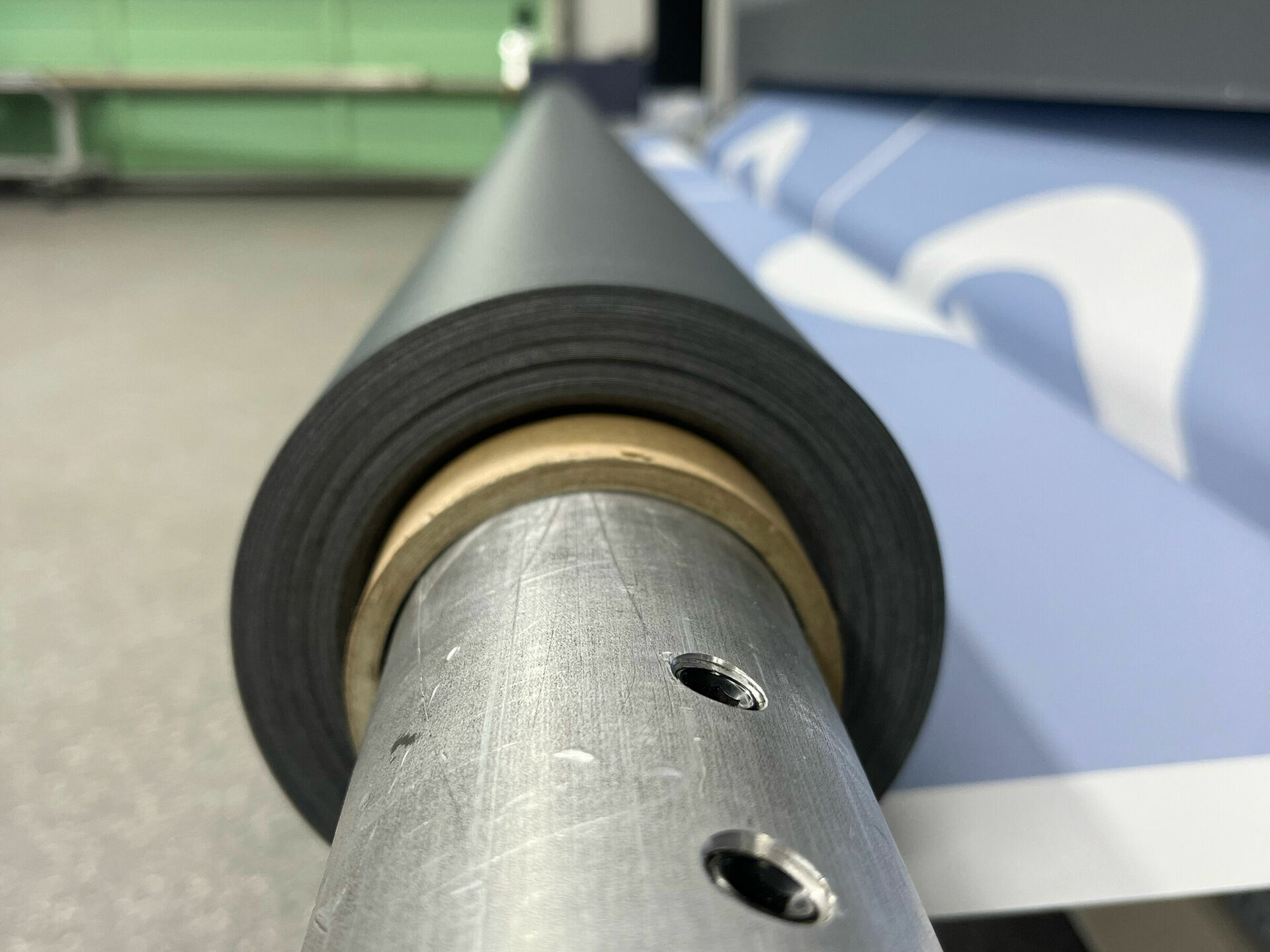

- High-speed printing: up to 3,800 sq ft/hour, followed by calendering

- Water-based dispersion inks (solvent-free)

- Perfect for interior applications

- Great for acoustic panels or versatile ceiling sails that enhance room aesthetics and sound quality

You may have noticed white breakage on printed clothing, like a T-shirt or sweater. It happens when the ink layer cracks or breaks, especially when the material is folded or creased. The fabric peeks through the cracks, disrupting the uniform appearance of the print. This issue is something to consider when choosing between UV and dye-sublimation printing.

Both UV and dye-sublimation printing are key to creating large-format digital prints. As a bonus, Procedes Group also utilizes another printing technology: 3D printing.

Although it doesn’t involve digital printing in the traditional sense — since it uses filaments instead of inks and constructs components rather than printing on substrates — 3D printing is essential for producing spacers, connectors, and other elements that complement our digital print projects.

![[Translate to English:] Round textile sculptures in white hang from the ceiling.](/fileadmin/_processed_/f/7/csm_cta-procedes_b2c2ad64de.jpg)