Innovative designs and unconventional shapes — ceiling sails unlock a room’s potential and boost well-being.

-

How about bringing a forest to the ceiling of a room?

-

Or suspending a car above, seemingly floating?

-

Maybe turning a warehouse into an office with designated quiet zones?

-

Or elegantly concealing the ceiling of an exhibition hall?

Ceiling sails offer countless possibilities when they are seamlessly suspended in place. They can blend harmoniously into a room or create deliberate accents, adding character and structure. These design elements make a significant impact: they enhance a space’s atmosphere and improve acoustics in workplaces and public areas. Sail through this article with us to discover how ceiling sails can transform your spaces.

Now, who is about to hit the ceiling? This is what makes ceiling sails special:

Ceiling sail as design elements

When ceiling sails mirror the floor

Ceiling sails as space-defining solutions: Horizontal or vertical installation?

Ceiling sails improve acoustics

From offices and business spaces to event halls and retail, ceiling sails can enhance any room and elevate any design level. The possibilities for creativity are nearly limitless, with custom designs tailored for specific purposes. Key factors to consider include:

-

Shape: Should the ceiling sail be round, square, or have a unique shape?

-

Colors or motifs: Would you like a custom print, a solid color, or a sail that serves as a projection surface? Should it feature indirect lighting or a warm, wood-like finish while weighing less than an OSB panel?

-

Materials: Do you prefer light, airy, transparent fabrics or denser materials with more weight?

These considerations can be creatively combined for a stunning effect.

Interested in using ceiling sails as acoustic elements?

Choose slightly porous materials that have been tested for effectiveness.

Flying carpets are no longer just a fairytale — they’re a reality with ceiling sails. Especially in interior design, ceiling sails can mirror existing room motifs or enhance the color scheme, creating a cohesive look.

Want to make a car appear upside down as a striking feature at an event while also concealing the exhibition hall’s ceiling? We can do that!

With the right materials and open-pored textiles, ceiling sails create quieter environments. By disrupting sound waves, they reduce reverberation and lower noise levels, promoting better concentration and comfort in offices and public buildings.

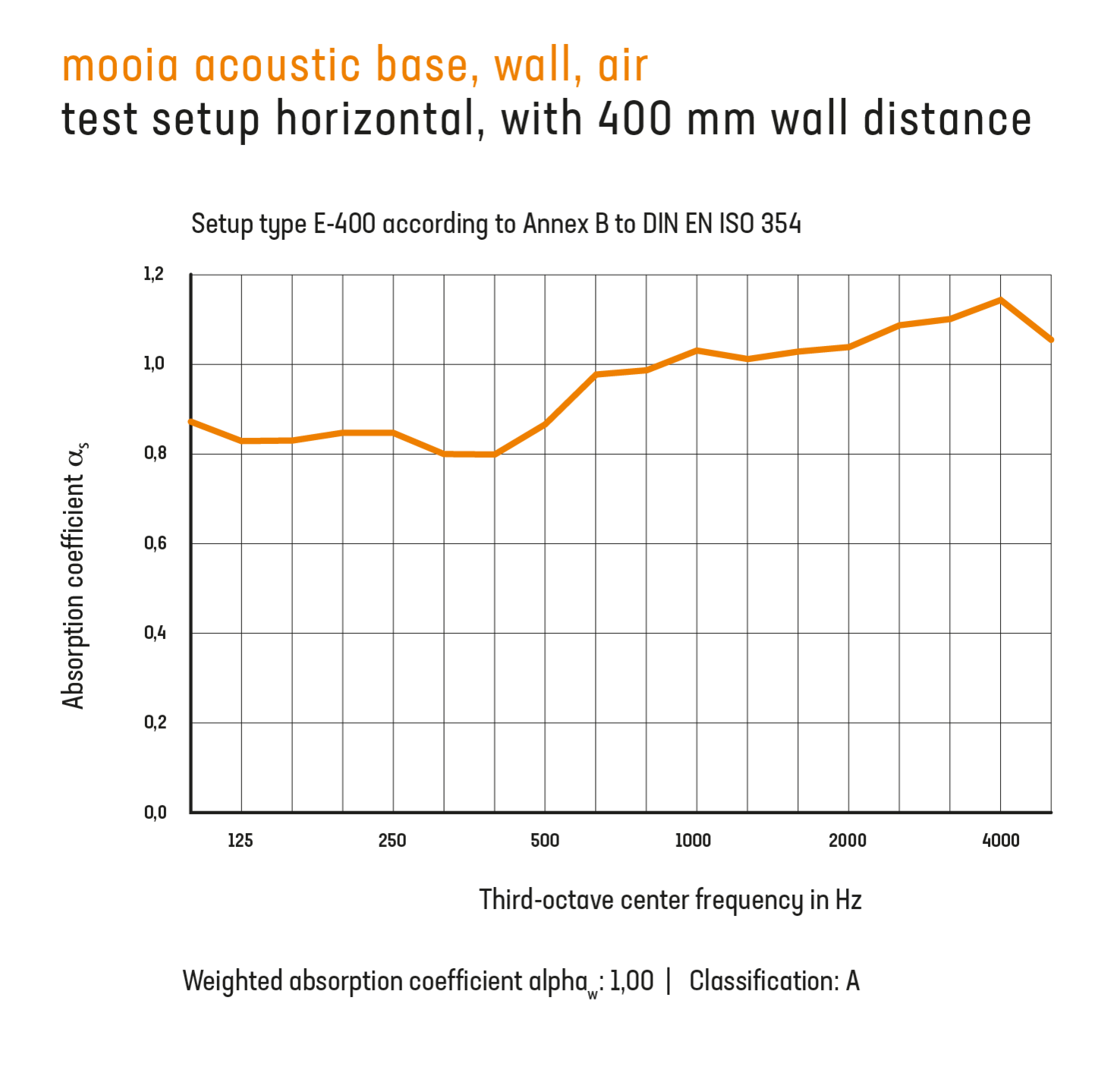

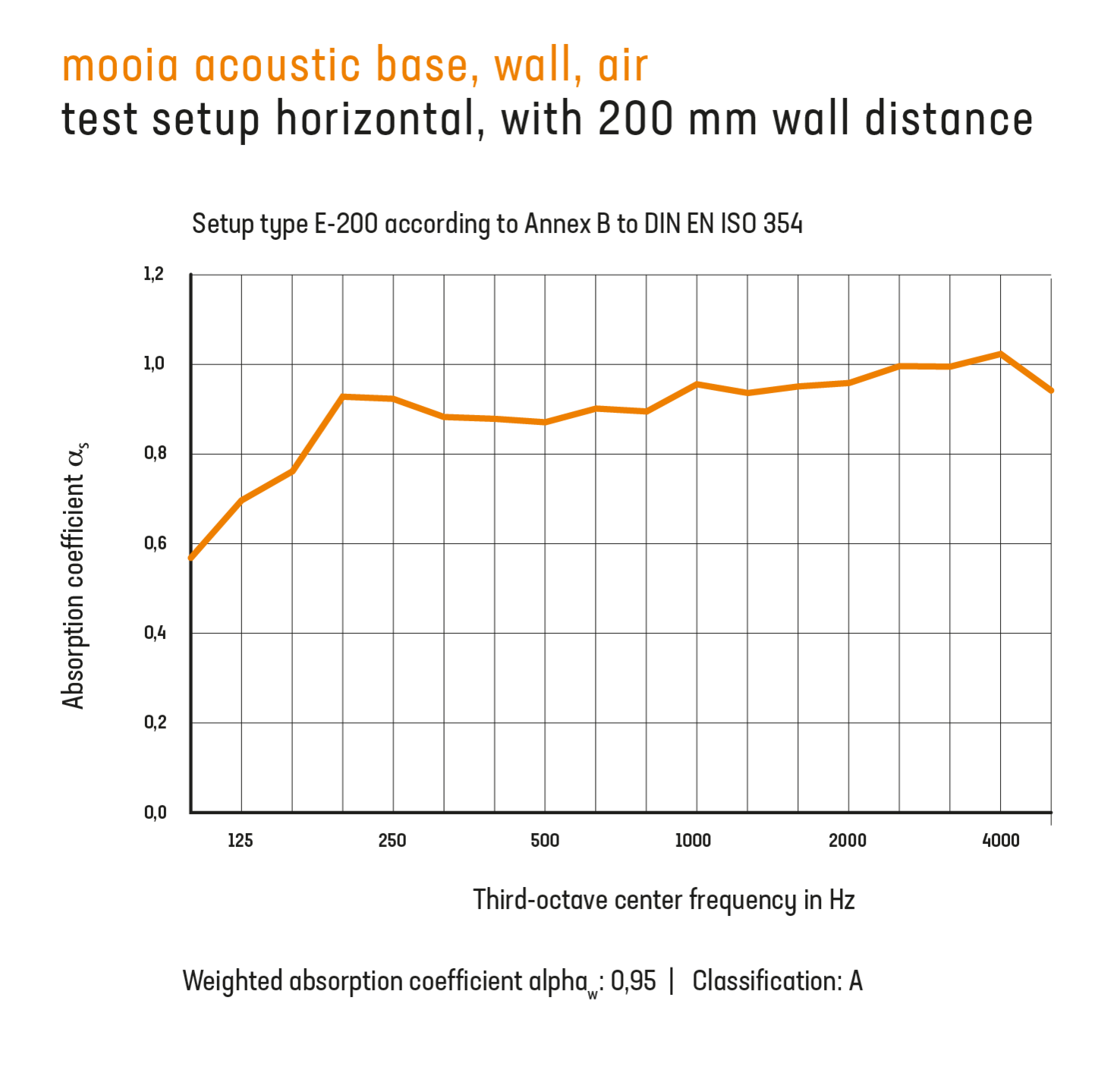

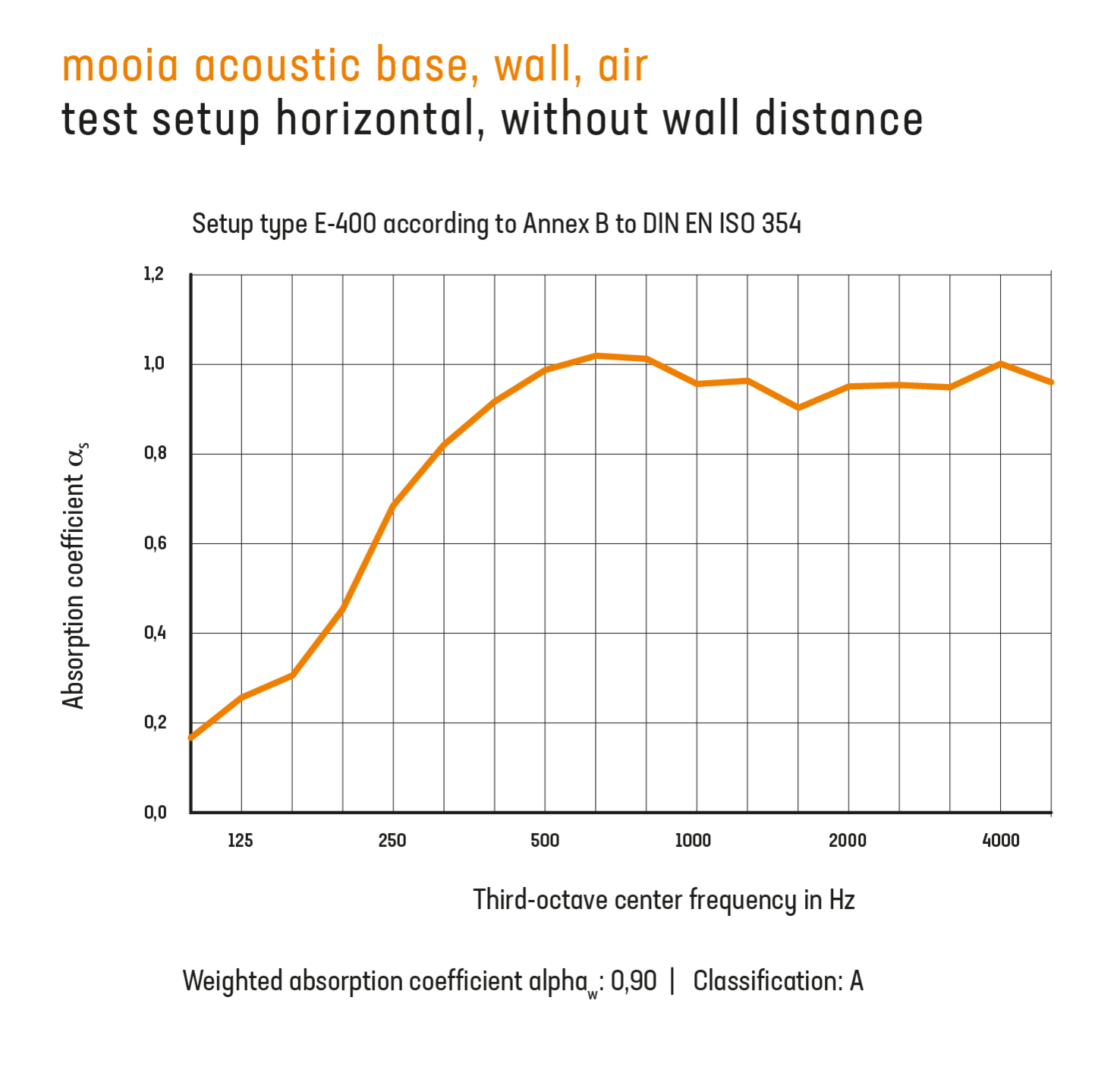

The optimal distance for ceiling sails to improve room acoustics is 16 inches from the ceiling. This measurement, based on standardized testing, ensures the best performance. Even at 8 inches, ceiling sails still deliver excellent acoustic benefits. Our procedes i-d designed sails have been tested using the reverberation room method to confirm their effectiveness.

Every space has its unique challenges, like existing light fixtures or speakers. Or the room has ceiling beams that make installation difficult. Think of our example from the tree nursery above.

In addition to the free choice of shape, motif and material, a major advantage of ceiling sails is that they can be easily adapted to the conditions of a room and accessories such as lights can also be integrated. And it gets even better: because you can combine the shapes. Or nest the ceiling sails. If you suspend several elements at different heights, you can create even more atmosphere in a room.

In modern buildings, concrete core activation uses pipes within the concrete to regulate temperature. Suspending ceiling sails directly beneath these activated ceilings can impact the heating or cooling effect. Vertical installations (baffles) offer a solution, and in cases where drilling isn’t allowed, lightweight, adhesive materials or independent beams may be used.

Trade show venues have strict fire safety regulations for structures and materials. For ceiling sails, this often means using sprinkler-compliant, water-permeable fabrics to ensure sprinklers function properly. Vertical sails also provide an option for meeting these requirements. All materials must generally meet Class B1 flame-retardant standards.