Quality, service, and precision are values my great-grandfather established, and we still uphold them in our portfolio today.

Developing products that can endure extreme conditions is in my blood — and my family’s, too — because it all started with my great-grandfather’s sailmaking business. Over three generations and a wealth of know-how, our Procedes printing plant in Lemwerder, near Bremen, was built. Today, we process up to 4,500 square meters of fabric daily, and our approach to every order remains the same: with the utmost care and passion. We carry the spirit of sailing, a tradition of over 100 years, into our work and team culture. With this DNA, we continue to steer in the right direction.

From sailmaking to Procedes: Over 100 years of textile expertise

To understand Procedes, a look at our history helps. It began in 1919, before the advent of sublimation printing or other modern techniques, with meticulous craftsmanship. My great-grandfather, Friedrich Beilken, founded a sailmaking business in Bremen-Vegesack, primarily producing sails for peat barges. My grandfather, Bernhard Beilken, took over, moving the business to a larger site in Lemwerder. Together with my uncle Hans and my father Berend, they transitioned to producing sports sails during the economic boom of the 1950s and 60s, as recreational sailing grew in popularity, and the company became one of Europe’s largest sailmakers.

We understand material demands as experienced sailors

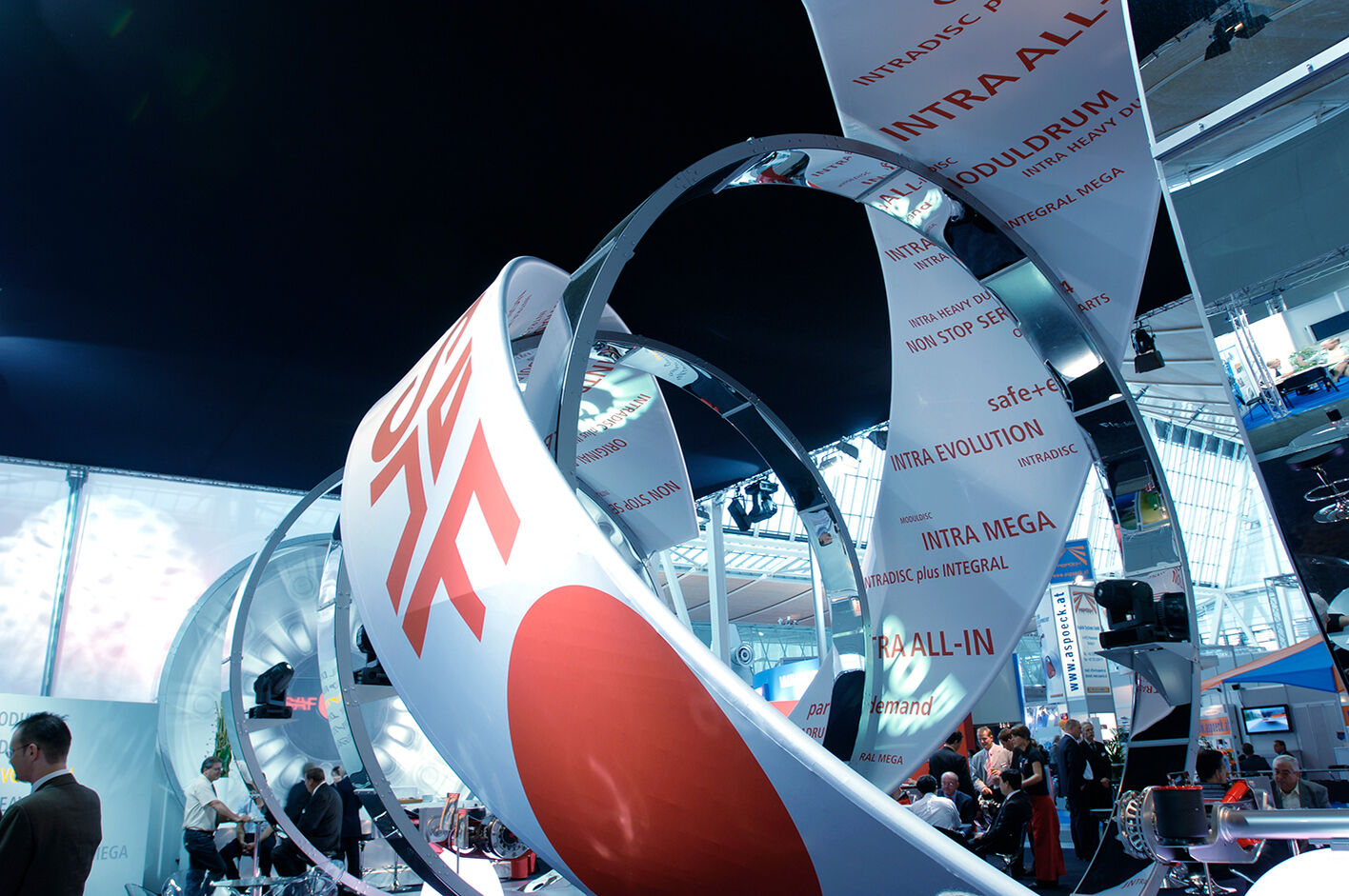

My father, Berend Beilken, carried the family name into the sailing world, becoming the first German skipper to win the Admiral’s Cup with Beilken sails. In the 1980s, he envisioned manufacturing surf sails, but resistance from a conservative industry led him to sell the business. Shortly after, he met Procédés Chénel, one of France’s largest exhibit companies at the time. They had developed an innovative, lightweight paper that transformed exhibition stand construction. Combining their expertise, my father founded Procedes in 1990, producing aluminum profiles and printed paper. By the mid-90s, digital printing became a game-changer, and we invested early, specializing in printing on textiles.

Fulfilling orders that move from receipt to dispatch in just a few hours requires true teamwork. Like a ship’s crew, our departments operate hand in hand, understanding their roles are equally important in achieving the final goal. Our strength lies in this coordinated effort, which is why we are where we are today.

Our quality standards: Large formats that meet every demand

Processing up to 4,500 square meters of fabric daily requires maintaining consistent quality. Our century of experience in fabric processing, sewing, and bonding ensures we achieve this. We know how to attach textiles to structures, maintain stability, and execute work with precision, thanks to our sailmaking heritage. Early on, we developed our own aluminum profiles, drawing on our sailing knowledge. For example, the coordination between a sail and mast must be perfect to achieve maximum speed, and this principle guides our construction designs today.

Our technical team ensures all requirements are translated into practical formats, while our metalworking shop creates lightweight frames that keep textiles wrinkle-free, making your exhibition stand truly shine.

Quality assurance begins on our doorstep

Outdoor projects present unique challenges, as textiles must withstand harsh weather conditions. We test materials rigorously in real-life scenarios. A banner we produced decorates the banks of the Weser near our Lemwerder site, providing a view for our employees and a test case for UV resistance and durability. Real-world conditions often differ from theoretical expectations, so we perform aging and stress tests based on internally defined protocols.

We assess:

- color vibrancy

- print quality

- crease resistance

- and how well the material can be cut and processed

Manufacturers involve us in their development phases right from the start

As Managing Director, it is particularly important to me that we are and remain an innovative company. That's why we are always on the lookout for new materials, colors (or inks in our jargon), tools and why we value sustainability through green printing. We are lucky that many manufacturers involve us directly in their development phase. This means, for example, that when the major textile companies in Germany drive their development forward, we are the source of ideas. Or they ask us to test materials directly in the factory.

Driving innovation and digital solutions

We began with traditional printing but quickly embraced digitalization, fully transitioning as the technology advanced. This has given us a significant edge.

For example: If a forklift damages a banner at an event, we can deliver a replacement swiftly because we store your print data digitally. With a fast workflow, our team knows exactly what to do, and our in-house programmers keep everything running smoothly. We can automate processes efficiently, a competitive advantage in our field.

Precision is paramount in our work, and we invest in cutting-edge technology to achieve it. We use advanced sewing machines that maintain consistent tension over long distances, ensuring flawless processing. Our facility handles around one million square meters of textile annually, and we were among the first in Germany to adopt five-meter-wide, fully automatic cutting machines. This ensures accuracy to the millimeter, even over long stretches.

From a “backyard garage” to 8,000 square meters of production space

Fun Fact: Some visitors think we operate out of a small garage—until they see our 8,000-square-meter facility. Their astonished reactions always make us smile.

I am proud that Procedes has already made a name for itself in exhibition stand construction. We also offer interior design within our production facility. Thanks to a finer finish, we can offer you the additional function of acoustics and also serve a different market. We transfer our Procedes know-how to room acoustics, for example, and produce large-format pictures that improve the sound in rooms such as offices. Feel free to drop by, we are always happy to welcome visitors to our premises in Lemwerder.

![Das Segel einer Sportjacht. [Translate to English:] Das Segel einer Sportyacht](/fileadmin/_processed_/9/1/csm_thom-milkovic-egUpLk34J4s-unsplash_dd06af8349.jpg)

![[Translate to English:] Round textile sculptures in white hang from the ceiling.](/fileadmin/_processed_/f/7/csm_cta-procedes_b2c2ad64de.jpg)