When you walk through our doors in Lemwerder, you're first greeted at reception. Maybe we’ll take you to our showroom. Or to one of our offices—with a beautiful view of the River Weser. And of course, a coffee to go with it. But wait! That all sounds great — but chances are, you won’t be visiting us in person. What a pity! Your project, however will reach us. Digitally.

And then what?

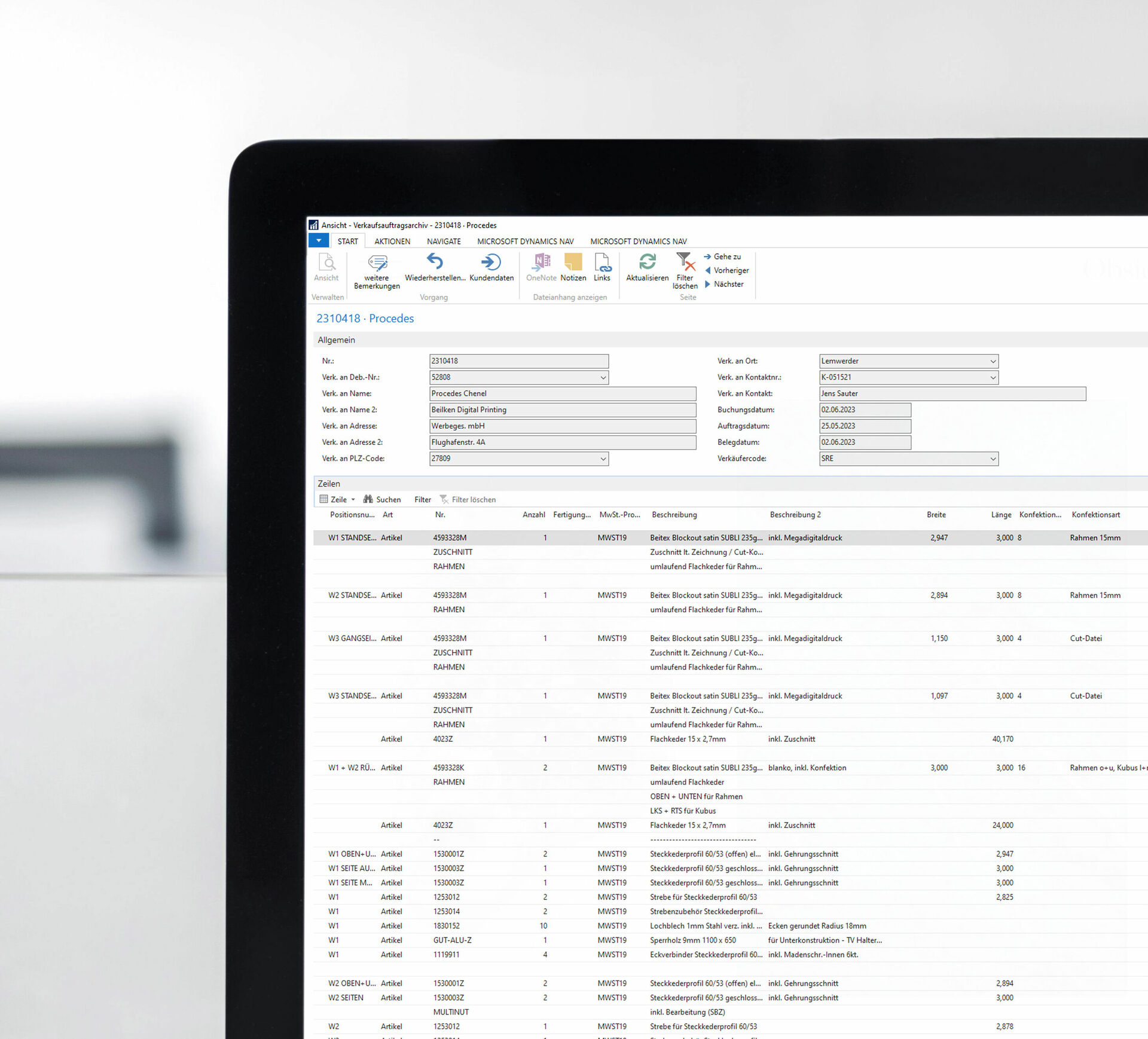

All project information across all trades is gathered in our project manager system. It’s the heart and foundation of our workflow. Every order is assigned a unique project number, which allows all team members to instantly see what the project is and what needs to be done. That’s essential in a company like Procedes, where many people and departments must work together seamlessly.

The project management software also helps us prevent miscommunication between departments — ensuring that everyone is working from the same information and reducing the risk of errors in production.

Customer data is carefully checked in the system:

- Are all necessary details provided?

- Have all required print files been submitted?

- Is everything technically feasible?

This allows us to clarify any questions directly with the customer — before production begins — and helps us avoid unnecessary delays or interruptions.

Speaking of production:

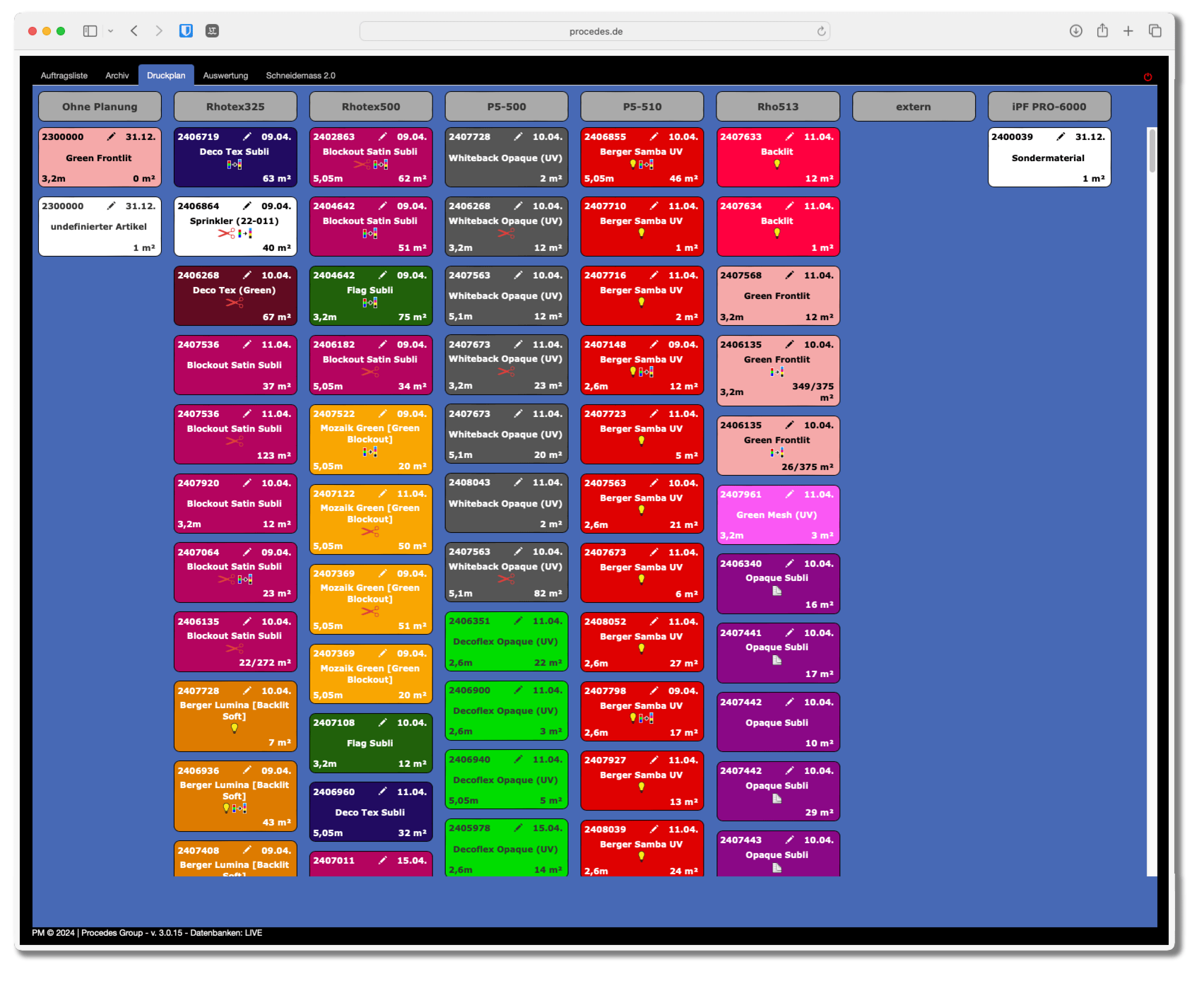

This is also where the entire production process is planned and scheduled across all departments. Machine allocation and its availability, schedule for the other trades, schedule for the graphics - everything that is needed for a successful project.

Once the project has been finally checked, the journey continues to the other trades: the graphics department, printing, finishing or aluminum processing.

Production – everything from a single source

Once a project enters production, it never has to leave our Procedes facilities until completion. We handle every step of the process in-house. A product that goes through all of our departments follows this path:

- Graphics Department: We check and process the data we receive from our clients. Too small, too large, wrong color space, or unsuitable for the intended material? Then we get back in touch. We make the necessary adjustments and consult with the client to ensure the best possible result.

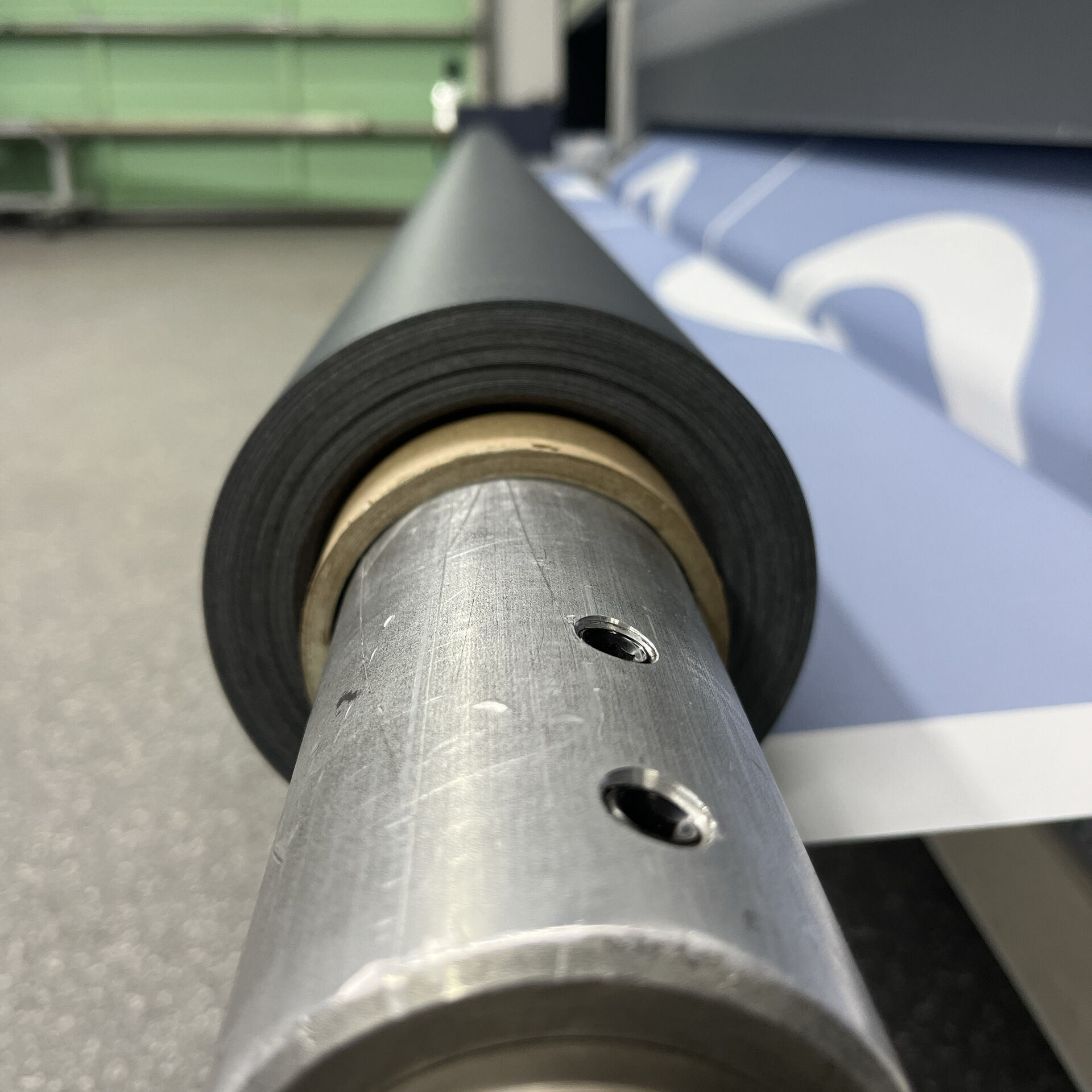

- Printing: Whether UV printing or dye-sublimation – we choose the right printing method for each project. We rely on some of the largest and most advanced printers on the market and continually optimize our equipment to stay at the cutting edge.

- Ready-made Department: Ready-made is our largest department at Procedes. This is where printed textiles are cut, sewn, and fitted with silicone edging for mounting. All machines and workflows here are specifically configured to meet our needs.

- Shipping: We even have an external logistics company located on-site in Lemwerder that works exclusively for Procedes. In close cooperation with our shipping department, we can offer highly customized shipping solutions—whether we’re sending oversized formats, special shapes, or standard products.

The Procedes claim: Individually coordinated projects

Thanks to our well-integrated workflow, most errors in the Procedes system are detected quickly. A common one: transposed numbers. A trade show wall is ordered at 3.52 meters in length, but the plans show 3.25 meters – our graphics department catches this automatically, because the format of the print file no longer matches. If needed, we follow up with the client and clarify the correct dimensions. We also frequently catch typos or file errors – and address them before they become a problem..

Across all departments, our team relies on the data stored in the project manager to access order details – such as special processing requirements, custom shapes, or other specifics. In the shipping department, the system provides a clear overview and automatically generates labels and tags based on the information from the ERP system. This ensures each item can be clearly identified—during shipping, by the client, or at the event itself.

Once the shipment leaves our facility and is on its way to the customer, the order is marked as complete in the ERP system, and the invoicing process is triggered.

Especially with highly customized projects, our consistent core workflow allows us to focus on the finer details.

All our clients benefit from two things: our well-established, refined processes — and our individual technical expertise.

This is especially crucial in the areas of graphic preparation and color management. Red is not just red — it appears differently depending on the material it’s printed on.

Our clients also rely on our expertise in textile finishing. Depending on how and where a material is mounted, it may be stretched or distorted during installation. In the worst-case scenario, this can alter the appearance of the printed design.

Our production schedules are usually tightly timed. That’s why thorough consultation in advance is especially important. We discuss materials, graphics, and components in detail—so that our workflow can run as smoothly and efficiently as possible. If in doubt, we prefer to create a test print or mock-up at the beginning of the project. That way, the client can clearly see what we’re talking about. These test setups often reveal new possibilities for us as well. An extra eyelet here or a custom solution there? No problem—as long as it’s planned in time!

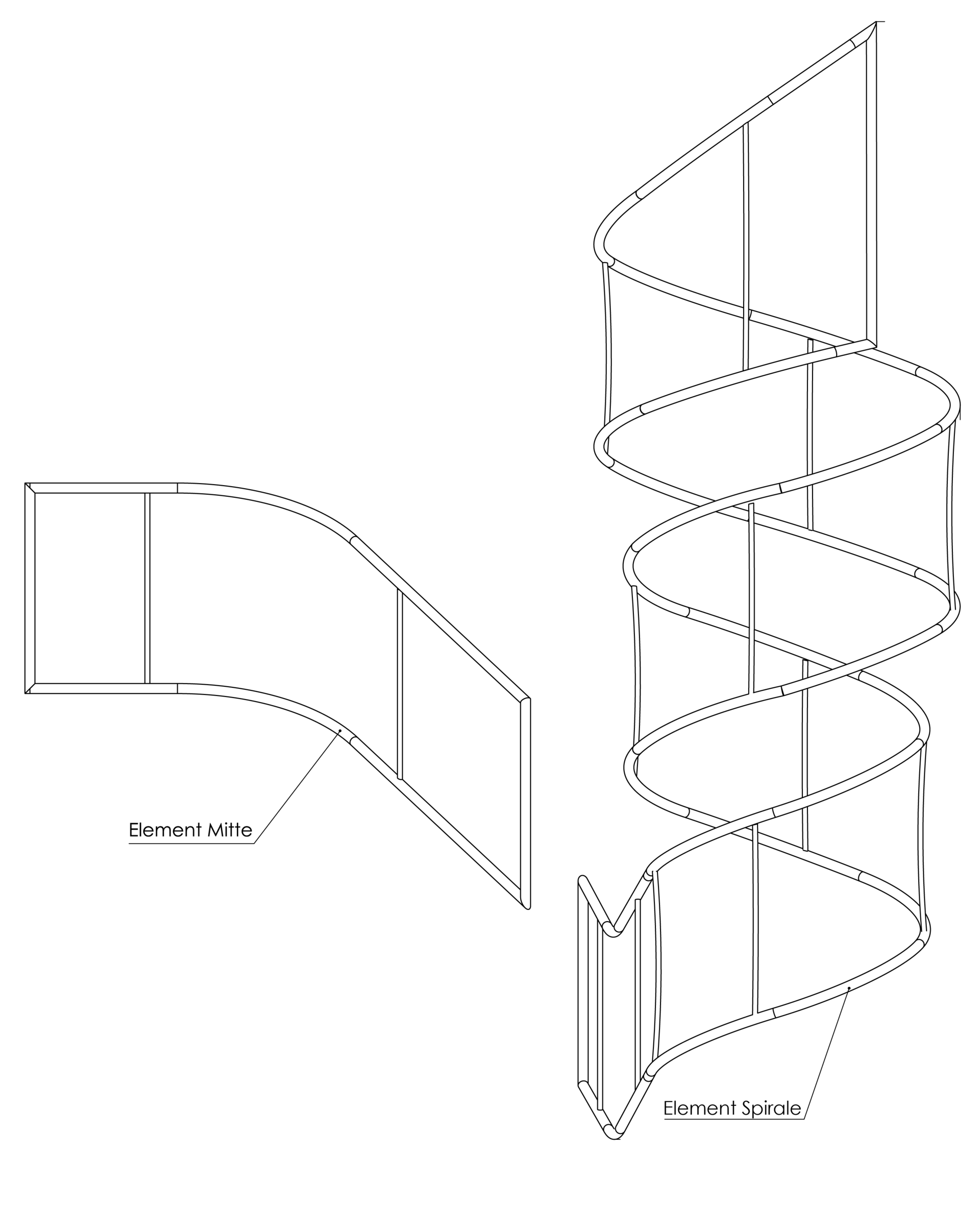

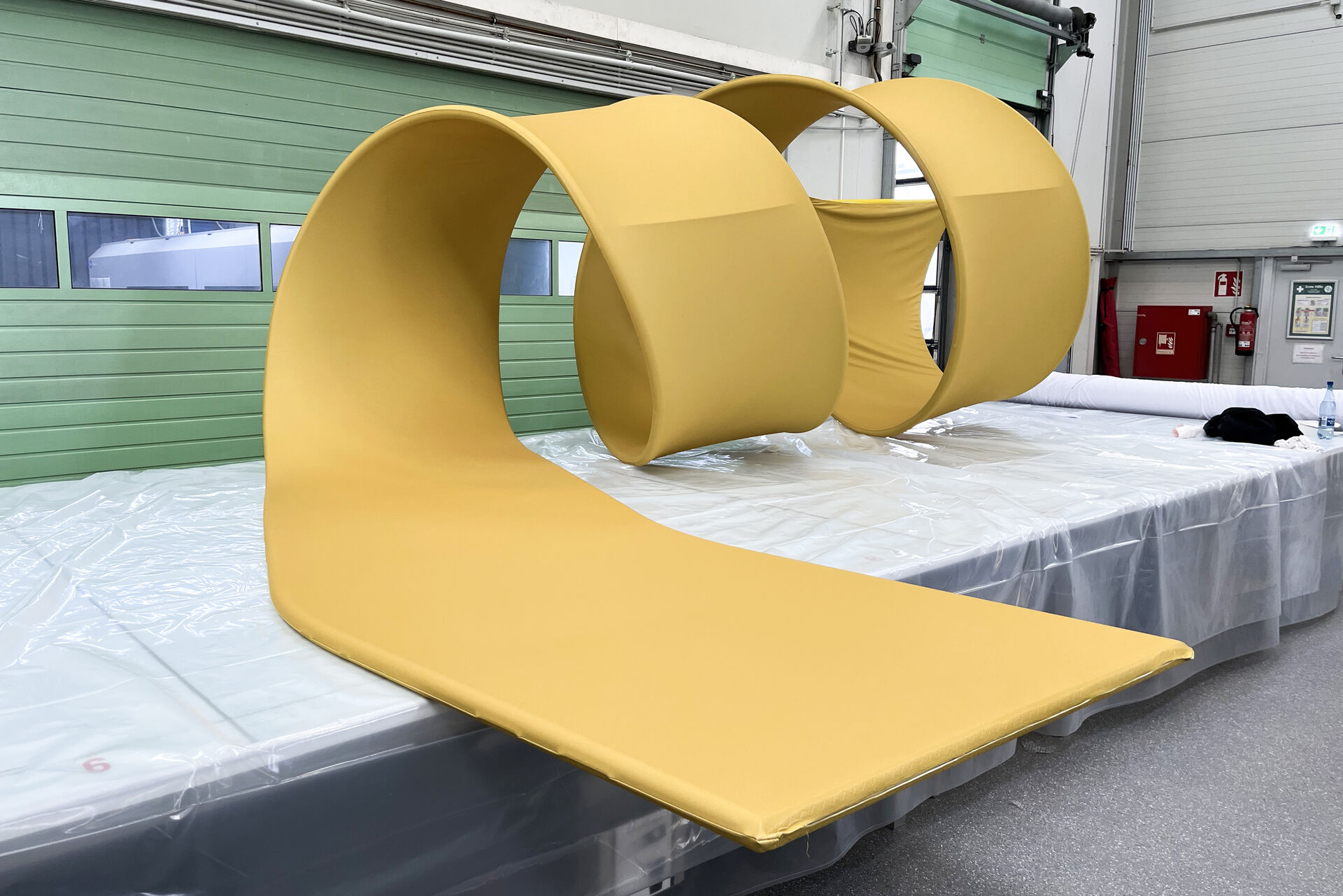

That's exactly what we did recently for the German Television Award: A curved torch, 3.5 meters tall, built from aluminum and covered with fabric—our first full-scale prototype stood right here at our facility in Lemwerder!

By the way, custom projects also help us to continuously optimize our workflow. Sometimes they really push us to our limits — and that’s exactly why we love what we do. These kinds of projects force us to rethink, restructure, and refine our processes.

Take this example: For a major automotive manufacturer, we built several large-scale constructions — fabric-covered elements that needed to look like wooden walls. While the basic shapes were often similar, each wall had to be tailored to the specific hall size of the trade show and the vehicle presentation it accompanied. That required some serious planning and problem-solving up front.

But we’re still benefiting from those learnings today! And the processes we developed through that experience are now firmly anchored in our project manager system — accessible to all departments and trades involved.

![[Translate to English:] Round textile sculptures in white hang from the ceiling.](/fileadmin/_processed_/f/7/csm_cta-procedes_b2c2ad64de.jpg)