At a political level, attempts are being made worldwide to counteract this development and a rethink has begun. However, it is uncertain whether the speed of implementation will be sufficient to halt this process.

For the time being, the rapid and drastic increase in ecological sustainability is an outstanding issue for everyone and therefore also for every company. Against this backdrop, medium-sized companies in Germany have two options for dealing with the issue of ecological sustainability:

One: companies can react to increasing regulatory requirements and try to meet them. This way of acting makes a company a driven one. Changes must always be implemented under duress and with a deadline, otherwise there is a threat of sanctions. The issue of ecological sustainability has a negative connotation because it has to be worked on under constant time pressure.

Alternatively, you can live up to your responsibility towards future generations and proactively tackle the increase in ecological sustainability in advance. As a pioneer, you have every opportunity to shape this form of implementation - creative ideas and disruptive approaches are required. Participation in a project to improve the world is easy for every employee, as intrinsic motivation is addressed. The topic has a positive connotation and requirements for change are not perceived as a burden, but as a success. All regulatory requirements are met before they come into force and there is no time pressure. As the Procedes Group, we have opted for this form of implementation.

The decisive criteria for buying our products are no longer just price, quality and availability - the criterion of ecological sustainability is increasingly becoming the focus of shoppers. The motto “the trend is your friend” is more valid than ever and, in the case of sustainability, it is a megatrend that is here to stay and has no alternative.

As a medium-sized company, we are not yet required to comply with any statutory reporting or documentation obligations. However, this would not be a problem for Procedes, as we have been working on this topic for years. Initially, this was driven by the approach of cost efficiency. In recent years, this has changed; amortization periods and return on investment considerations are no longer the sole decision-making criteria, but one of many.

For our industry, trade fairs are still “marketplaces of the modern age”: People meet at a central location, trade and exchange information about products. This experience is difficult to replace with digital formats. And this also applies to our products such as banners, frames and ceiling sails.

But hand on heart, our industry is not entirely unproblematic in ecological terms with regard to the end product trade fair:

- Products for trade fairs are only used for a very short time. Custom-made structures and banners hang for an average of one week.

- Then they have often been disposed of in the past. Sometimes components can be reused. Unfortunately, many things cannot.

- Travel and transportation to trade fairs can be associated with higher emissions. Especially if, for example, many kilometers are flown.

- The digital printing industry is very energy-intensive. Large printing machines and various printing processes require energy or heat.

- This also applies to cutters in the ready-made department or machines in metal processing.

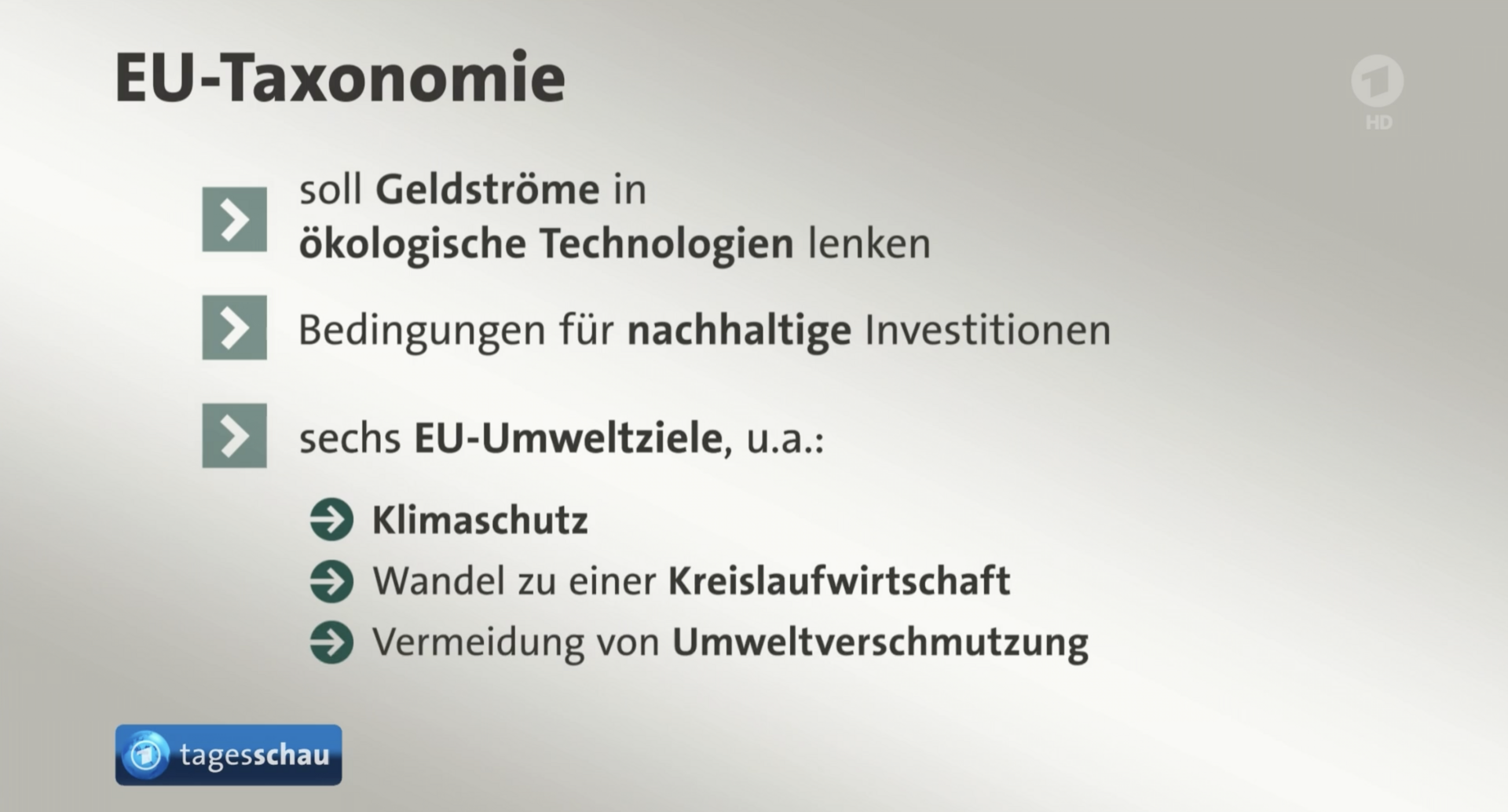

In addition, the EU wants to become climate-neutral by 2050 across all sectors. The EU taxonomy obliges large companies to act and report more sustainably. This also applies to cooperation with their partners.

EU taxonomy - what exactly is it?

With the EU taxonomy, our end customers must ensure that all their actions are verified in terms of environmental sustainability. They must report annually on how sustainable they are. These reports are intended to make it easier for investors to decide to invest in climate-friendly companies:

As a result, our end customers in the trade fair & event sector tend to work with digital print shops that are already sustainable. Or assign corresponding guidelines to their stand builders, who pass them on to the printers or look for sustainable suppliers for print products. Our printing industry could then transfer some of these requirements to suppliers. Every position in the supply chain is challenged and we as the Procedes Group are an important part of this chain. That's why we are already taking the sustainable path, which will come with no alternative anyway.

Digital printing companies for live communication face the challenge that:

- no uniform standard for the objective quantification of sustainability has yet been established in our sector and standards from other sectors (construction industry) can only be applied to a limited extent.

- data collection to determine the ecological effect of the specific business unit is time-consuming and resource-intensive. Without a well-founded survey, it is not possible to develop a targeted strategy or formulate a standard.

Here are our recommendations for the

implementation of a clearly structured process:

-

As in any project, communication is crucial for success. As a rule, it should not be particularly difficult to spark motivation for this topic through target group-oriented communication. Everyone likes to be a “savior of the world”.

-

Define a team with clear responsibilities to work on the topic. The head of the team must have sufficient influence to ensure that individual work packages within the entire company are processed in a binding manner. No one within an organization is happy about extensive data collection with a corresponding amount of work.

-

Seek qualified external support for independent monitoring of the project.

-

Carry out the most comprehensive data collection possible with regard to ecological effects. Ensure that the survey is carried out carefully and comprehensibly by qualified persons. In the course of the initial survey, it should be ensured that this data can be collected consistently and reproducibly on a regular basis.

-

Analyze the results of this survey and derive specific areas of action to improve environmental sustainability step by step.

-

Quantify the individual areas of action in terms of the ecological effect, the investment volume and the implementation period.

-

Start by implementing the most effective, simplest and most favorable areas of action (low hanging fruits first).

-

You will find that you are dependent on partners from the entire value chain in many areas. Seek an exchange with your customers and suppliers - perhaps together you can achieve an increase in ecological sustainability.

Sustainable printing companies: The Procedes Group set out years ago to become the most sustainable digital printing company for live entertainment

Admittedly, as already mentioned, sustainability was not on our agenda from the outset. We rather came to it via a “detour”. A good 15 years ago, we were primarily concerned with the idea: How can we produce more efficiently while using less energy? As a result, we converted our lighting and printer components to LED, for example. Or, when building a new factory building according to energy criteria, we also considered a photovoltaic system. We planned it in such a way that it fully utilizes the roof area, which significantly reduced the amortization period. It was also about making a contribution to sustainability, but at the time we only acted selectively. We now have a centrally managed sustainability strategy and have developed into one of the most environmentally sustainable digital printing companies for live entertainment in Europe.

The sustainable operation of a business unit is a decisive success factor - this is already anchored in the term. A company that does not act sustainably deprives itself of the basis for its existence. Against the backdrop of growing awareness of the importance of sustainable action, the pace of this basic principle has accelerated. Companies that do not act sustainably will be excluded from the market faster than ever before.

With our sailmaking DNA, we have developed from a small manufactory into a company with a production area of 8,000 m2. At peak times, we process 4,500 m2 of textiles a day. This is a great responsibility, of which we are aware.

Determine your carbon footprint and reduce emissions with Scopes 1, 2 and 3 of the Greenhouse Gas Protocol

The CO2e footprint is one way of approaching the topic of environmental sustainability. All emissions are expressed in CO2 equivalents (CO2e). The CO2 footprint of a company is completely individual. But which areas emit CO2 and how do you identify them? And where can you start in the company to save CO2?

Structuring the recording of CO2e emissions according to the Greenhouse Gas Protocol (GHG Protocol) is recognized practice. We have therefore started to record our emissions according to Scopes 1, 2 and 3 of the GHG. Scopes 1, 2 and 3 are areas in which greenhouse gas emissions can arise in companies.

Scope 3 comprises all other indirect emissions, upstream and downstream along the entire value chain, i.e. both before and after our own business activities. This includes emissions from areas such as the procurement of raw materials and primary products, logistics, business travel and employee commuting.

Of course, it takes some effort and good processes to determine your own carbon footprint. However, companies gain a better understanding and feel for how they can avoid emissions. This is how we proceeded:

The evaluation of Scope 1 and 2 should be quick to implement in most companies and provides initial indications. The effort involved in Scope 3 is many times greater, as the entire value chain is considered here.

| What we have already accomplished: | What we have planned on the way to Net Zero by 2032: |

|---|---|

| ● For 15 years, we have been continuously increasing our energy efficiency by using state-of-the-art production machinery and infrastructure | ● Complete switch to electricity as an energy source in Scope 1 and 2 |

| ● Our photovoltaic system produces around 25% of our electricity in a CO2-neutral way, and we make surpluses available to other consumers, thereby displacing CO2-emitting electricity generation, | ● Maximizing the sustainable self-generation of electrical energy |

| ● We purchase gas and electricity from the market with maximum CO2 neutralization | ● Increasing the use of self-generated renewable energy by implementing energy storage solutions and intelligent energy management to increase self-consumption |

| ● We operate a highly efficient heating system | ● Development of more ecologically sustainable product groups |

| ● Continuous reduction of CO2e emissions in logistics through local sourcing. Reduction of arrivals and departures through bundling and more compact packaging | ● Continuous improvement of energy efficiency in the production process |

| ● Constant increase in the proportion of recycled materials purchased | ● rolling review of the supply chain to increase the use of sustainable materials and logistics processes |

| ● Creating incentives to reduce CO2 emissions for employees' commuting behavior | |

| ● Waste optimization enables waste avoidance in the production process | |

| ● Consistent separation of waste fractions in order to enable single-variety processing | |

| ● Incentives for avoiding business air travel and car journeys |

With our transformation concept, we will achieve Net Zero in Scope 1 and 2 before 2032.

If every company within a value chain implements this transformation, then the entire process is fully sustainable. Scope 3 is the biggest challenge. Companies like to ignore Scope 3 because it is very complex. However, it holds huge savings potential:

We take the CO2 savings potential so seriously that we have really analyzed and documented the entire workflow chain with regard to the following question: Which items cause emissions?

As an example, we found that large amounts of CO2e are emitted during the transportation of our products from Lemwerder to end customers. Unfortunately, we have little influence on the logistics industry to offer CO2-neutral transportation. Nevertheless, we can use our opportunities and make a (small) difference, e.g. by bundling transportation.

While you can achieve a lot yourself in the areas of Scope 1 and 2, this is not so easy in Scope 3. Here, it is all the more important that we bring the entire value chain for graphic products to the table. That strong market players are prepared to invest in greater sustainability. That we develop strategies together with our partners on how to reduce emissions. Only through a joint effort to improve the entire process in conjunction with an individual transformation of each process participant can sustainable action be successful.

![[Translate to English:] Round textile sculptures in white hang from the ceiling.](/fileadmin/_processed_/f/7/csm_cta-procedes_b2c2ad64de.jpg)